About us

COMPANY

Founded in 1994, CHIULAN s.r.l. has become, over the years, a competitive manufacturer of welded steel structures, thanks to its quality, promptness, production capacity, and, last but not least, the flexibility demonstrated in every project.

The production factory located in Caransebeș can deliver up to 600 tons of welded steel structures per month, with approximately 60 direct production employees with extensive experience in the field, assisted by specialized engineers.

Metalwork and structural elements are manufactured in compliance with current technical and quality standards, complemented by the special requirements of designers and clients.

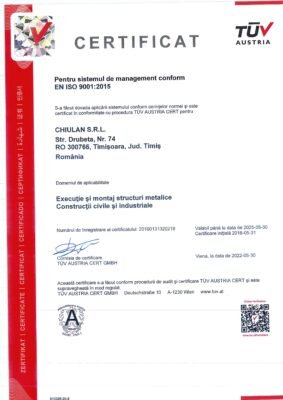

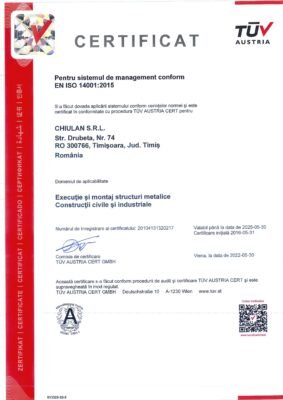

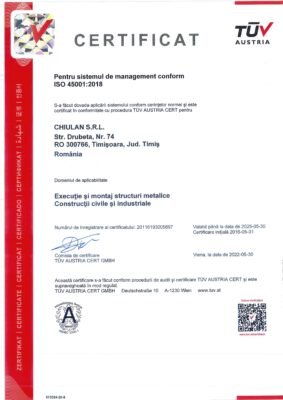

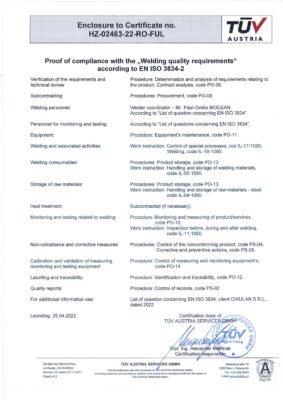

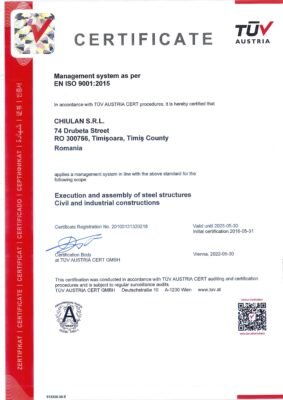

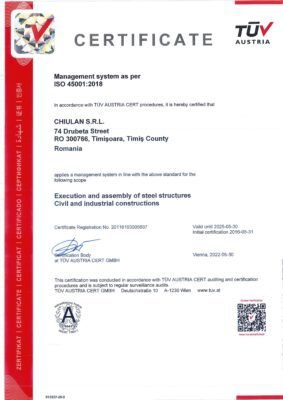

The equipment used is state-of-the-art. The company maintains an integrated management system for Quality, Environment, and Occupational Health and Safety (ISO 9001, 14001, 45001), a system certified by TUV CERT Austria.

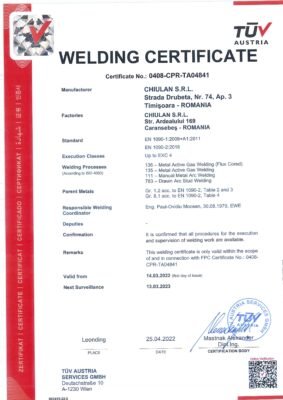

Furthermore, the company has approved welding procedures, and all the welders are authorized by TUV CERT Austria and ISCIR Timișoara.

We hold TUV certification for in-factory execution in compliance with the EN1090 standard, EXC4 class, international welding engineer, as well as certified personnel and equipment for non-destructive weld testing (visual, penetrant liquids, magnetic particles, ultrasonic).

We use Tekla Structures for product detailing and our own software developed on the Apple platform for scheduling, preparation, and real time monitoring of production. Thus, our client can know at any moment – in real time – the production status of any component in the order.

Where required, we can also provide the assembly of steel structures with our own specialized teams, having the necessary proven experience.

In recent years, we have delivered over 3,500 tons of steel structure annually, and we have installed closure systems with sandwich panels, cassette systems – wool – sheeting, high-rib sheeting and wool for roofing (over 2,000,000 sq m).

CAPABILITIES

We can manufacture steel structure assemblies with dimensions of up to 24 meters in length, 5 meters in width, 3.5 meters in height, and a maximum weight of 20 tons. Under very special conditions, we can handle parts up to 60 tons.

The list of main available equipment is as follows:

- 1 double-girder overhead crane of 20 tons, 3 overhead cranes of 10 tons, 2 overhead cranes of 5 tons, 1 overhead crane of 2.5 tons, Konecranes

- CNC plasma and oxy-fuel cutting machine, 1 cutting head, 3000 × 13000 mm, maximum thickness 40 mm for plasma and 120 mm for oxy-fuel

- 20 kW laser cutting machine, 3000 mm x 12000 mm, maximum thickness 50 mm for carbon steel

- Yaskawa Robotic welding station with Esab Mig/Mag power source for welding assemblies of up to 1,5 m in width and 13 m in length

- Roesler automatic blasting installation, max sections 400 mm x 800 mm

- Gietart Sprint 2.6 automatic blasting installation, max sections 2500 mm x 600 mm

- >12 pulsed-current welding installations, over 350 A, EWM

- Painting installations: airless, airmix, and liquid electrostatic

- Manual blasting booth 5.0 m x 5.0 m x 15.0 m

- Painting booth 4.0 m x 4.0 m x 15.0 m

- Equipment for ultrasonic and magnetic powder inspection

- Covered and heated production spaces of approx. 5,000 sqm

- 100 tf hydraulic press brake

- Lathes, milling machines, drilling machines, punching machine, and other equipment.

Română

Română