Oxy-fuel Cutting

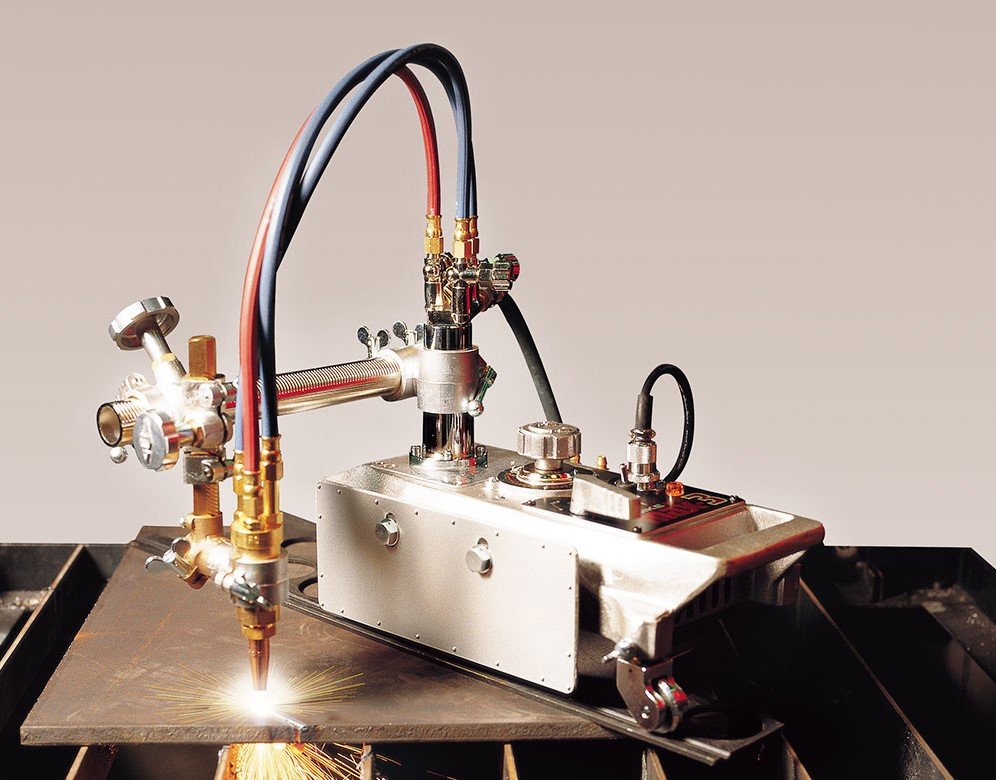

OXY-FUEL CUTTING

The CNC oxy-fuel cutting service offered by Chiulan SRL is the ideal solution for efficient steel processing, ensuring quality and precision in accordance with the most demanding industrial standards.

WHAT IS OXY-FUEL CUTTING

Oxy-fuel cutting is a technological process used for cutting and processing metals by using a mixture of oxygen and a fuel gas, such as acetylene, propane, or methane. This process involves using an intense oxy-fuel flame to melt and remove material from the cutting or processing area.

Oxy-fuel cutting can be used to cut a variety of metals, including carbon steel, stainless steel, and aluminum. It is also more economical than other cutting technologies and can be used outdoors, where other methods might encounter difficulties.

CNC OXY-FUEL CUTTING

We are ready to meet even the most complex requirements of our clients, offering a wide range of options and services tailored to your needs:

- Thickness : between 6 and 120 mm

- Width : up to 3.1 m

- Length : up to 13 m

The material can be supplied either by the client or from our current stock, offering you flexibility and convenience. We have materials such as S235JR or S355J2 available, ensuring that your quality requirements are met.

The cutting quality is guaranteed to fall within range 3–4, according to the IS 9013 standard, ensuring that your parts are processed precisely and according to specifications.

Additionally, we can provide part marking by stamping, offering you clear and precise identification of your products.

OXY-FUEL CUTTING – ADVANTAGES

- Precision and quality: Our CNC oxy-fuel cutting process guarantees high precision and exceptional cut quality, ensuring perfect parts and flawless finishes.

- Flexibility: Our ability to work with materials of various thicknesses and custom sizes allows us to efficiently and promptly meet the specific needs of each project.

- Production efficiency: The use of CNC technology streamlines the cutting process, reducing required time and minimizing material waste, which leads to increased production efficiency.

- Wide range of materials: We offer the option to use material supplied by the client or from our current stock of high-quality steel, such as S235JR or S355J2, ensuring we meet the durability and strength requirements of every project.

We are dedicated to providing you with customized and reliable solutions for your needs.

Contact us today to discuss your specific needs and to receive a personalized offer.

Send a request for a quote now to office@chiulan.ro and we will respond as soon as possible!

REQUEST A QUOTE

Română

Română